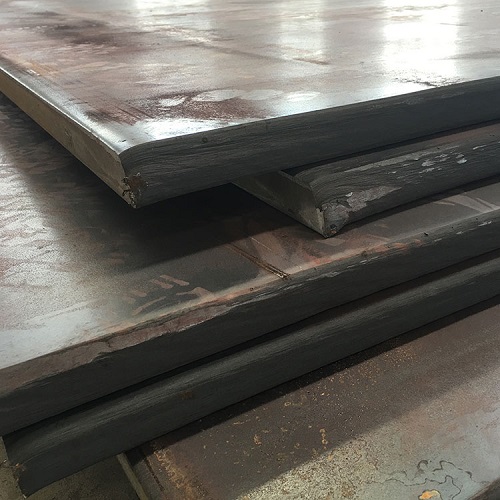

ʻO nā pā kila pale ʻaʻahu:

(1) NM360 (360 pale ʻaʻahu)

Kapa inoa: ʻO N ke kū'ē (nai) ʻo M ka leka pinyin mua o nā huaʻōlelo Kina ʻelua no ka wili ʻana (mo), a ʻo 360 ka awelika o ka paʻakikī Brinell o kēia mau papa kila.

Hoʻomaʻamaʻa wela: ka wela wela kiʻekiʻe, hoʻopau + hoʻoulu (quenching and tempering)

Noi: Hoʻohana nui ʻia ka pepa kila pale NM360 i nā mīkini mining, nā mīkini eli lanahu, ka honua.

Hoʻohana pinepine ʻia ʻo ia e like me ke kila structural kiʻekiʻe me ka ikaika hua ≥ 700MPa.ʻO ka mea maʻamau ka hāʻawi ʻana i ka pale no nā manawa a i ʻole nā ʻāpana e pono ai ke ʻaʻahu ʻia, i mea e ola lōʻihi ai nā mea hana, e hoʻemi i ka downtime mālama ʻia e ka mālama ʻana, a me ka hoʻemi ʻana i ka hoʻopukapuka kālā.

Hana: ʻOi aku ka hua ma luna o 800, a ʻoi aku ka ikaika tensile ma luna o 1000.

(2) NM400

ʻO ka NM400 he mau papa kila ikaika loa.Loaʻa i ka NM400 ka ikaika mechanical kiʻekiʻe;ʻO kona mau waiwai mechanical he 3 a 5 mau manawa ma mua o nā pale kila haʻahaʻa haʻahaʻa;hiki iā ia ke hoʻomaikaʻi nui i ka pale ʻana o nā ʻāpana pili mechanical;pēlā e hoʻomaikaʻi ai i ke ola lawelawe o nā mīkini a hoʻemi i nā kumukūʻai hana.ʻO ka paʻakikī o ka ʻili o kēia huahana maʻamau i 360 ~ 450HB.ʻO nā papa kila hoʻolālā kūpono no ka hana ʻana a me ka hana ʻana i nā ʻāpana kūʻokoʻa a palupalu no nā mines a me nā mīkini hana like ʻole.

Hoʻohana nui ʻia ka pepa kila pale NM400 i nā mīkini hana, nā mīkini mining, nā mīkini eli lanahu, nā mīkini pale kaiapuni, nā mīkini metallurgical a me nā ʻāpana huahana ʻē aʻe.ʻEli, mea hoʻouka, pā bakeke bulldozer, pā lihi, pā lihi ʻaoʻao, maka.ʻO nā liner crusher, nā lau.

(3) Mn13 (ke kila manganese kiʻekiʻe)

ʻO ka Mn13 he kila kila kūʻokoʻa manganese kiʻekiʻe (HIGH MANGANESE STELL SCRAP), ʻo ia ka koho maikaʻi loa ma waena o nā mea ʻaʻahu e like me ka hopena ikaika a me ke kapa kiʻekiʻe.

ʻElua mau hiʻohiʻona nui o ke kila manganese kiʻekiʻe: ʻo ka mea ʻoi aku ka nui o ka hopena o waho, ʻoi aku ka kiʻekiʻe o ke kūpaʻa ʻana o kona ʻili ponoʻī.Ke hoʻopā ʻia, e piʻi koke ka paʻakikī o ka ʻili mai HB200 a i luna o HB700, no laila e hana ana i kahi ʻāpana ʻili-pale.ʻO ka austenite i loko o ka papa o loko o ka pā kila e mālama mau ana i ka paʻakikī hopena maikaʻi;ʻO ka lua, ʻo ia me ka ʻaʻahu mālie ʻana o ka papa paʻakikī o ka ʻili, e hoʻomau ka hana ʻana o nā papa hana hou.

ʻO ka pā kila Mn13 i ʻōwili ʻia he kūpaʻa maikaʻi loa i ka ʻaʻahu hopena ikaika a me ka ʻaʻahu koʻikoʻi kiʻekiʻe, ʻaʻole e haki i ka wā e hoʻohana ai, a loaʻa iā ia nā mea machining maʻalahi e like me ke ʻoki, wili, a me ke kuʻi.

ʻO ka hao hao chromium kiʻekiʻe i hoʻohana maʻamau, ʻoi aku ka maikaʻi o ka pale ʻana i ka lole no ka neʻe ʻana.Hiki i ka Mn13 ke ho'ēmi i ke kumukūʻai o ka hoʻohana ʻana i nā ʻāpana o nā lako, mālama i nā kumukūʻai mālama pono, a hoʻomaikaʻi i ka hoʻokūkū o nā huahana i hoʻopau ʻia.

Eia nō naʻe, ʻo ke kūpaʻa ʻana o ke kila manganese kiʻekiʻe e hōʻike ana i kona kūlana kiʻekiʻe ma lalo o nā kūlana kūpono e hana i ka paʻakikī o ka hana, a ʻilihune i nā hihia ʻē aʻe.

ʻO ke kila kila Mn17 maʻamau e hoʻonui i ka nui o ka manganese ma ke kumu o ke kila Mn13, kahi e hoʻomaikaʻi ai i ka paʻa o ka austenite a pale i ka ua o ka carbide, a laila e hoʻomaikaʻi ai i ka ikaika a me ka plasticity o ke kila a hoʻomaikaʻi i ka hana. hiki ke paakiki o ke kila.a me ka pale ʻana i ka abrasion.No ka laʻana, ʻo ke ola lawelawe o nā ala kaʻaahi ZGMn18 i hoʻohana ʻia ma ke kūkulu ʻākau he 20% ~ 25% kiʻekiʻe ma mua o ka ZGMn13.

ʻO nā māka a me ka laulā o ka hoʻohana ʻana i ke kila manganese kiʻekiʻe i hoʻohana mau ʻia ma Kina: ZGMn13-1 (C 1.10%~1.50%) hoʻohana ʻia no nā ʻāpana haʻahaʻa, ZGMn13-2 (C1.00%~1.40%) hoʻohana ʻia no ʻāpana maʻamau, ZGMn13- 3 (C0.90% ~ 1.30%) hoʻohana ʻia no nā ʻāpana paʻakikī, a hoʻohana ʻia ʻo ZGMn13-4 (C0.90% ~ 1.20%) no nā ʻāpana hopena kiʻekiʻe.ʻO ka maʻiʻo manganese o nā papa kila ʻehā ma luna nei he 11.0% a 14.0%.

No ke kuʻi ʻana a me ka hoʻoponopono ʻana, pono e koho ʻia nā electrodes manganese-nickel austenite (type D256 a i ʻole D266), me kahi kikoʻī lōʻihi a lahilahi, φ3.2mm × 350mm, a ʻo ka uhi waho he alkaline.Hoʻohana ke ʻano hana i ka pilina hoʻohuli DC, ka liʻiliʻi o kēia manawa, nāwaliwali arc, liʻiliʻi welding bead a me nā papa wili he nui, a mālama mau i ka haʻahaʻa haʻahaʻa a me ka wela haʻahaʻa.E kuʻi i ka wā e wili ai e hoʻopau i ke kaumaha.Pono e ʻike ʻia nā hewa koʻikoʻi.Hiki ke hoʻohana ʻia ka welding flash (Swiss GAAS80/700 flash welding machine) a i ʻole ka welding MAG (e like me Nissan YD-S-500) no ka wiliwili koʻikoʻi, hiki ke hoʻopaʻa pono i nā waiwai mechanical seam.

Pākuʻi 1: Ka manaʻo o ka paʻakikī

ʻO ka paʻakikī kahi papa kuhikuhi hana e ana i ka palupalu a me ka paʻakikī o nā mea.Nui nā ʻano o ka hoʻāʻo ʻana i ka paʻakikī, ʻaʻole like nā kumumanaʻo, a ʻaʻole like like nā waiwai a me nā manaʻo i ana ʻia.ʻO ka mea maʻamau, ʻo ia ka hoʻāʻo paʻakikī o ka haʻahaʻa ukana, ʻo ia hoʻi ʻo Brinell hardness (HB), Rockwell hardness (HRA, HRB, HRC), Vickers hardness (HV), rubber plastic Shore hardness (HA, HD) a me nā mea ʻē aʻe. hiki i ka ili o ka mea ke pale aku i ke komo ana o kekahi mea paakiki.ʻAʻole maʻalahi ka paʻakikī o ke kino, akā he hōʻailona hana piha e hōʻike ana i ka elasticity, plasticity, ikaika a me ka paʻakikī o nā mea.

ʻO ka paʻakikī o ke kila: ʻO ka inoa inoa o ka paʻakikī metala ʻo H. E like me nā ʻano hoʻāʻo paʻakikī like ʻole, aia nā ʻōlelo ma lalo nei.

●O nā ʻōlelo maʻamau ʻo Brinell (HB), Rockwell (HRC), Vickers (HV), Leeb (HL) paʻakikī, a me nā mea ʻē aʻe, ma waena o ka HB a me ka HRC i hoʻohana pinepine ʻia.

● He nui ka hoʻohana ʻana o HB, a hoʻohana maʻamau i ka wā palupalu ka mea, e like me nā metala non-ferrous, ke kila ma mua o ka mālama ʻana i ka wela a ma hope paha o ka annealing.He kūpono ka HRC no nā mea me ka paʻakikī o ka ʻili kiʻekiʻe, e like me ka paʻakikī mālama wela, etc.

ʻO ka ʻokoʻa ma waena o nā mea ʻelua he ʻokoʻa nā probes o nā mea hōʻike paʻakikī.He mau pōpō kila ka ʻimi o ka mea hōʻike paʻakikī Brinell, ʻoiai he mau daimana nā ʻimi o ka mea hōʻike paʻakikī ʻo Rockwell.Ma lalo o kekahi mau kūlana, hiki ke hoʻololiʻia ka HB a me ka HRC ma ka nānāʻana i ka papaʻaina.Hiki ke hoʻopaʻa ʻia kona ʻano helu noʻonoʻo e like me: 1HRC≈1/10HB.

●HV-kūpono no ka nānā ʻana microscopic.ʻO Vickers hardness (HV) ua paʻi ʻia i loko o ka ʻili o ka mea me ka haʻahaʻa o lalo o 120kg a me ka indenter cone diamond square me kahi kihi vertex o 136 °, a ua māhele ʻia ka ʻili o ka lua indentation o ka mea e ka ukana. waiwai, ʻo ia ka Vickers hardness value (HV).Hoʻoholo ʻia ʻo Rockwell hardness (HR-) e ka hohonu o ka indentation plastic deformation e hoʻoholo ai i ka index waiwai paʻakikī.He maʻalahi ka hana, wikiwiki a intuitive, a kūpono no ka hana nui.

Pākuʻi 2: Ke kila hoʻohana maʻamau

ʻĀina (Wugang, Xingang, Wuhan hao a me ke kila, Nangang, Baosteel): NM360, NM400, NM450, NM500, NR360, NR400, B-HARD360, B-HARD400, B-HARD450

Kuekene kila pale lole: HARDOX400, HARDOX450, HARDOX500, HARDOX600, SB-50, SB-45

Ke kila ʻaʻahu ʻaʻahu Kelemania: XAR400, XAR450, XAR500, XAR600, Dillidur400, Dillidur500

Ke kila ʻaʻahu ʻaʻahu Belgian: QUARD400, QUARD450, QUARD500

Ke kila ʻaʻahu ʻaʻahu Farani: FORA400, FORA500, Creusabro4800, Creusabro8000

Ke kila aʻaʻahu Finnish: RAEX400, RAEX450, RAEX500

Ke kila aʻaʻaʻaʻa Kepani: JFE-EH360, JFE-EH400, JFE-EH500, WEL-HARD400, WEL-HARD500.

Ka manawa hoʻouna: Jan-29-2023